I like your thread alot! SOOO many pictures!

makes me happy!

haha it really helps for reference.

trace it out and use a small carbide dremel bit....

lol durrr...

i emailed the guy the made the carbon fiber panel, he says to use a flow of water while cutting it with a dremel so its doesn't get too dusty and wear gloves to prvent the dust from contacting the skin. he says its

10x more itchy than fiberglass

now thats a real helpful adice

so yea MORE UPDATES!!!

rain = free time for me... so i got started on the custom bezel for the s2k cluster. I didn't have any tools for this so i just did t the cave man way. laid it down on the conrete in my backyard and started going at it... lol. ghetto yes, but it got the job done... and with a little filling, it turned out nice. I'd rate it a 8.3/10 job... so iim going to even it out a tad bit more.

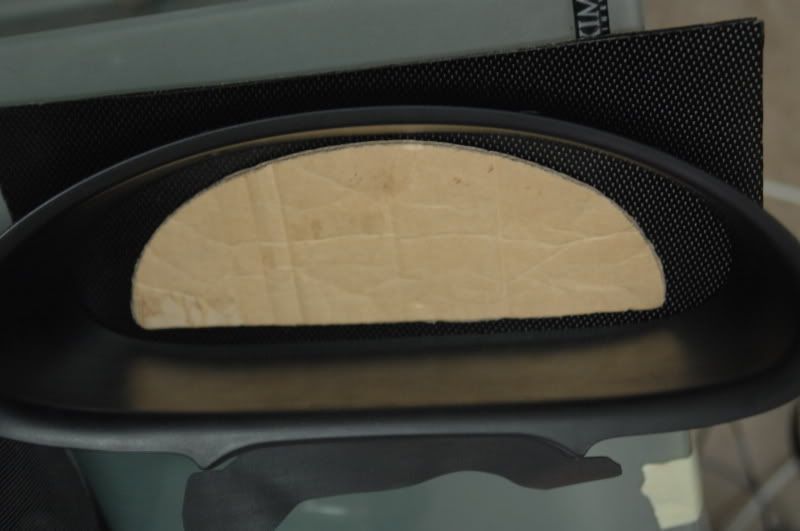

here's a cut out of the s2k cluster face, perfect cut out too, i shoulda kept the other side of the cut out, but i think i threw it out long ago when i made the template.

here's the problem with the integra bezel, its too curvy for anything to lay against it... so instead i grinded it down. i took pictures of both for comparison.

this is pretty much what its goign to end up being cut out. what do you guys think? its not like i have any other spots to locate/position the cluster... lol

so getting a white pen, making an outline... and buying some fine discs for the dremel will be the next task to get it going. Im not quite sure if i will use that black trimming on the s2k cluster... cause i might just screw the carbon fiber panel to it... we'll see when iwe get that far. :thumbup: