Last year I ran an off the shelf Wiseco piston

K594M845. This year I decided to go with custom Wiseco pistons because the higher compression OTS pistons are not designed for turbo (high HP)applications. They are lightened where strength is not needed for naturally aspirated apps. The bent wrist pin last year highlights the weaknesses. Custom pistons allowed us to reinforce the piston in all areas while running a big dome for higher compression.

-To keep things simple we started with the same dimensions as K594M845.

-Wiseco used their

HD1 forging from the 4G63 product line.

-Same skirt profile as K594M845, strutted pin boss and cut side skirts on non thrust sides

-We went with

84.9mm (3.344”) diameter because it would allow me to hone again and give me another rebuild without moving up a bore size. Plus I can still use an 85mm ring pack.

-Dome volume went from 8.25cc to

8.20cc.

-We increased the dome thickness from .150” to

.225”. K594M845 was as thin as .120” at the intake valve relief.

-We kept the valve reliefs the same, radius and depth.

-We discussed changing the pin offset from .030” to .020” to reduce thrust load. I was apprehensive about changing this because we planned to run a larger p2w clearance and this would make the pistons more noisy as well as allow the piston to tilt more possibly affecting p2h clearance therefore we kept it the same.

-My tuner wanted to cut a fire slot in the top of the dome to propagate flame travel. This was not possible without changing forgings as there was not enough material in the dome to cut and it would weaken the dome.

-We dropped the compression height from 1.181” to

1.176” to compensate for milling of the deck. 1.050” being the minimum compression height that still has maximum ring land thicknesses.

-We thickened the rings lands substantially. This makes the ring land area stronger and keeps heats away from the rings. Top ring went from .200” to

.300”. Second ring went from .140” to

.165”. Third is unchanged.

-We upgraded the wrist pin from S561, 5115 steel to

S733, 9310 tool steel.

-Piston weight increased from 279g to

338g.

-Pin weight increased from 68g to

108g.

-As before I had the domes ceramic coated and the skirts come moly coated.

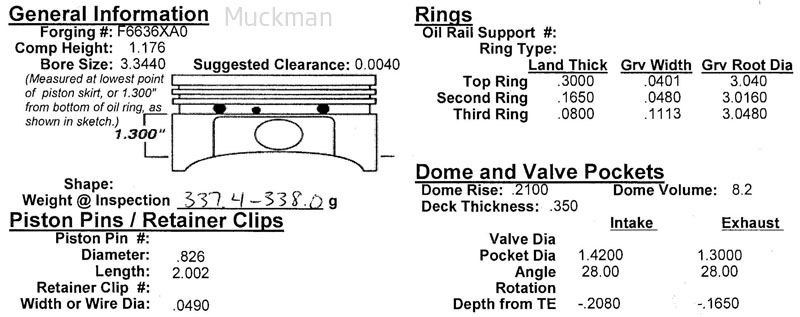

Here is the spec sheet for the custom pistons:

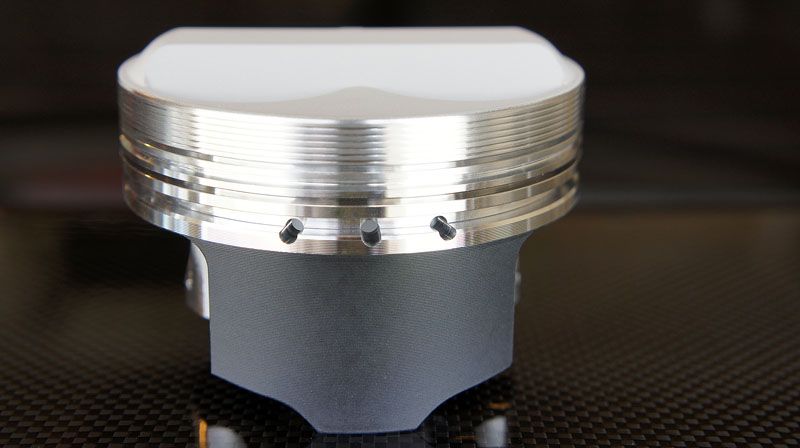

Here you can see the extra think ring lands, gas ports and lateral ring grooves.

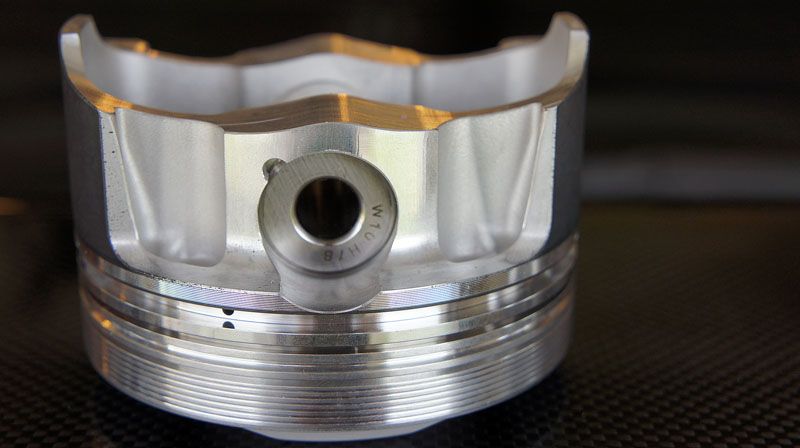

Partial skirts

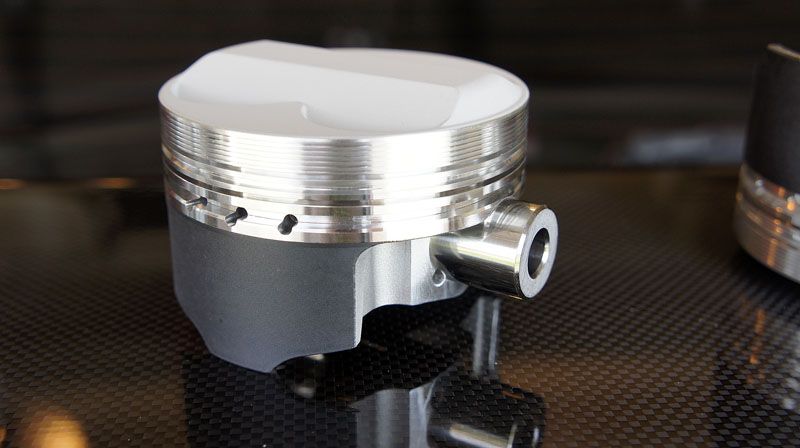

D battery wrist pin

Strutted pin boss and underside of dome.

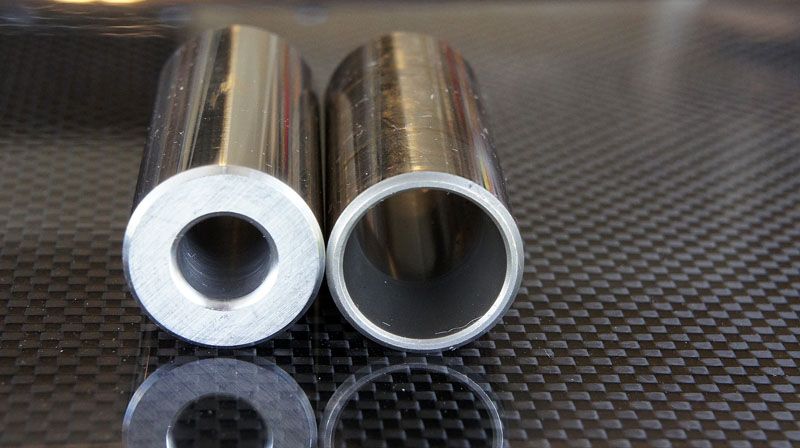

This makes me laugh. S561 .138” tapered pin vs S733 .225" straight walled pin.