Muckman’s High Compression Super Build

95B18BTurbo

New Member

Definitely useful information on how to check the v2v clearances! Thank you as I'll be using that info this week.

MrGurley

************5-0

fucking woot!!Definitely useful information on how to check the v2v clearances! Thank you as I'll be using that info this week.

Muckman

Not a M0derator

Nope just been serious about this hobby for a decade.So much technical info in this thread. :thumbs up

Muckman, are you an mechanical engineer or something?

Let me know if you guys have any technical questions. This build thread will become boring if its just pictures.Definitely useful information on how to check the v2v clearances! Thank you as I'll be using that info this week.

95B18BTurbo

New Member

Will do. The machine shop is almost done with the head/block, so it'll be time to work my magic here shortly.Let me know if you guys have any technical questions. This build thread will become boring if its just pictures.

Ted's Owner

On to Integra number two!

Simply amazing build thus far, Muckman. Subb'd.

Muckman

Not a M0derator

Fall 2012 - New guides and valve job

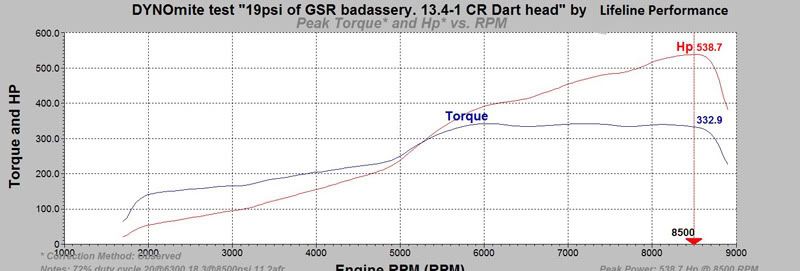

I ran this head last year with a full Supertech valve train and made 597hp. But on the dyno we noticed a sine wave developing in the torque curve that was indicative of turbulent head flow. The same curve was also trending in the fuel map. My tuner predicted it could be a sign of poor valve seal or valve timing. The man is a genius but I didn’t believe he could tell that from a fuel map.

Here is the wave in the torque line from 6 to 8k.

After the dyno I investigated further and ran a compression test.

It turns out #4 was low.

Cyl1-295psi

Cyl2-300psi

Cyl3-300psi

Cyl4-260psi

I wanted to be certain the piston rings weren’t the cause of the leaking so I added a cap full of oil to #4 and reran the compression test (wet test). The psi # didn’t go up at all which is good but I’m thinking maybe I didn’t add enough oil. I added another cap then reran the test which broke my fn compression tester! Oil must have went up the tube because the needle pegged out on the right side of 0. Now it reads 40psi all the time in free air. I need a Formula 1 compression tester! lol

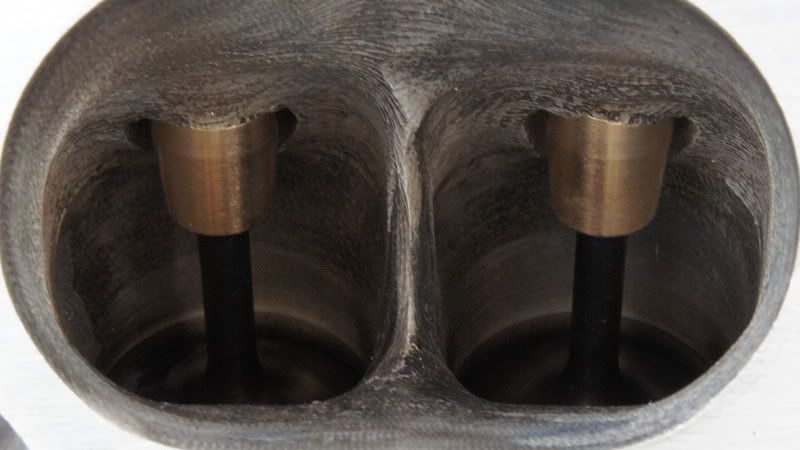

I wanted to replace the wrist pins anyways so I tore it down over the winter. A leak down test showed the valves were leaking. So I pulled both off manifolds to see better and removed the cams to be sure the valves were closed. I poured rubbing alcohol into the head ports and pressurized the cylinder with air. This allowed me to visually see the valves leaking in the form of air bubbles. It turns out 7 intake valves were leaking, and 6 exhaust valves were leaking. Was this a result of bent valves or something else?

This is what it looked like:

Here’s a video showing the pressure leaking past the valves.

When I pulled the intake manifold I found evidence of exhaust reversion in the intake runners, but mostly in #4. The intake valves were leaking combustion out the wrong side! Was this the cause of the sine wave shaped torque curve on the dyno? The intake valve stems were also oily. Oil was leaking past the new valve seals into the combustion chamber. Oil severely lowers the octane rating of fuel and can cause detonation. That’s amazing it made 600hp like this!

Here’s a picture showing the oily residue on the combustion chamber of the head.

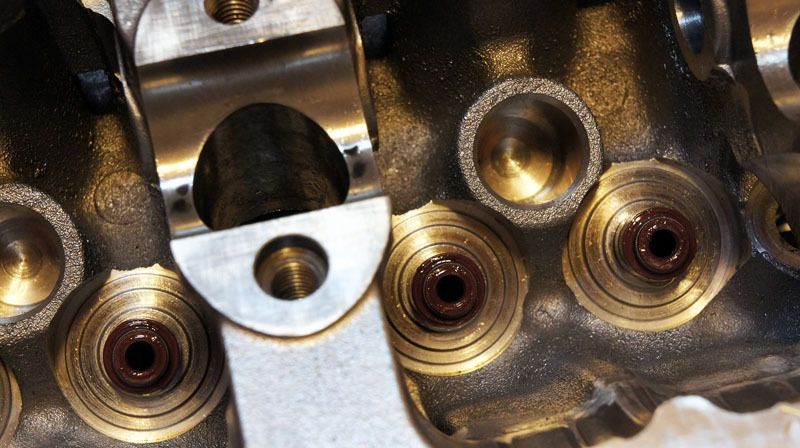

I took the head to my machine shop. They reported no bent valves but the valve guides are worn. The guides are allowing the valves to wobble .003" total which is beyond the service limit of .002". This caused the valves not to sit flush in the seat and caused them to get hammered out of round. They are able to grind the valves to fix the valve run out (out of round) and do a 3 angle valve job on the seats. We replaced the OEM steel guides with Supertech manganese bronze guides. My concern is the OEM steel guides were cut when the head was ported vs the new guides are only tapered so Im sure that will decrease head flow slightly. But cut guides dont support the valve stem as well which also could have caused the valve wobble.

New Supertech guides installed.

Vs old OEM guides which were cut for maximum air flow.

Lesson learned - Never trust a used head, even if it looks brand new. Get the head checked out!

I ran this head last year with a full Supertech valve train and made 597hp. But on the dyno we noticed a sine wave developing in the torque curve that was indicative of turbulent head flow. The same curve was also trending in the fuel map. My tuner predicted it could be a sign of poor valve seal or valve timing. The man is a genius but I didn’t believe he could tell that from a fuel map.

Here is the wave in the torque line from 6 to 8k.

After the dyno I investigated further and ran a compression test.

It turns out #4 was low.

Cyl1-295psi

Cyl2-300psi

Cyl3-300psi

Cyl4-260psi

I wanted to be certain the piston rings weren’t the cause of the leaking so I added a cap full of oil to #4 and reran the compression test (wet test). The psi # didn’t go up at all which is good but I’m thinking maybe I didn’t add enough oil. I added another cap then reran the test which broke my fn compression tester! Oil must have went up the tube because the needle pegged out on the right side of 0. Now it reads 40psi all the time in free air. I need a Formula 1 compression tester! lol

I wanted to replace the wrist pins anyways so I tore it down over the winter. A leak down test showed the valves were leaking. So I pulled both off manifolds to see better and removed the cams to be sure the valves were closed. I poured rubbing alcohol into the head ports and pressurized the cylinder with air. This allowed me to visually see the valves leaking in the form of air bubbles. It turns out 7 intake valves were leaking, and 6 exhaust valves were leaking. Was this a result of bent valves or something else?

This is what it looked like:

Here’s a video showing the pressure leaking past the valves.

When I pulled the intake manifold I found evidence of exhaust reversion in the intake runners, but mostly in #4. The intake valves were leaking combustion out the wrong side! Was this the cause of the sine wave shaped torque curve on the dyno? The intake valve stems were also oily. Oil was leaking past the new valve seals into the combustion chamber. Oil severely lowers the octane rating of fuel and can cause detonation. That’s amazing it made 600hp like this!

Here’s a picture showing the oily residue on the combustion chamber of the head.

I took the head to my machine shop. They reported no bent valves but the valve guides are worn. The guides are allowing the valves to wobble .003" total which is beyond the service limit of .002". This caused the valves not to sit flush in the seat and caused them to get hammered out of round. They are able to grind the valves to fix the valve run out (out of round) and do a 3 angle valve job on the seats. We replaced the OEM steel guides with Supertech manganese bronze guides. My concern is the OEM steel guides were cut when the head was ported vs the new guides are only tapered so Im sure that will decrease head flow slightly. But cut guides dont support the valve stem as well which also could have caused the valve wobble.

New Supertech guides installed.

Vs old OEM guides which were cut for maximum air flow.

Lesson learned - Never trust a used head, even if it looks brand new. Get the head checked out!

g3teg97

Super Moderator

I highly doubt that. 8)Let me know if you guys have any technical questions. This build thread will become boring if its just pictures.

Muckman

Not a M0derator

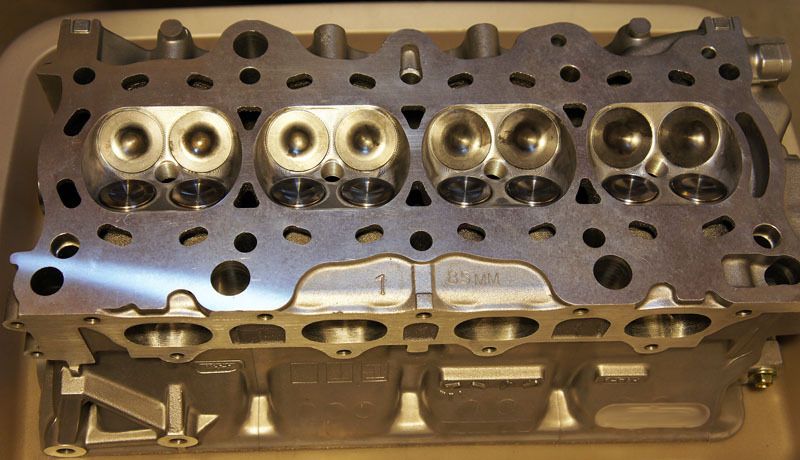

Now that I’m done with all the measurements and machine work I can finally assemble the complete head. I’m using a full Supertech valve train – valve seals, spring seats, dual valve springs, titanium retainers, keepers and of course valves – Oversized nitride intake valves and inconel exhaust valves.

HIVN-1001, intake valve +1mm dished nitrided

HEVI-1000, exhaust valve std dished inconel

SPR-H100DR, 85lbs seat pressure dual springs

SEAT-H1002D, valve seats

RET-K20A2-T2, titanium retainers

KPR-5.5-7, keepers

Cleaning the valve guides and installing the spring seats. A couple of the spring locators didn’t sit flat on the seat. It turns out the inner diameters were catching on the valve guides. A quick debur resolved that.

Installing the exhaust valve seals

Intake valve seals

Installing the valves. Dished valves are lighter than flat faced valves and I don’t need any more compression.

All the valves installed

All the valves, seats and seals installed

Cleaning the rockers, bolts and lost motion assemblies.

Preparing the springs and retainers.

Compressing the valve springs to insert the keepers. I love this valve spring compressor. It lets me compress the springs by myself and frees up both hands to insert the keepers. Impossible with a generic lever type compressor.

All the springs and retainers installed.

Here’s the finished pic in daylight

HIVN-1001, intake valve +1mm dished nitrided

HEVI-1000, exhaust valve std dished inconel

SPR-H100DR, 85lbs seat pressure dual springs

SEAT-H1002D, valve seats

RET-K20A2-T2, titanium retainers

KPR-5.5-7, keepers

Cleaning the valve guides and installing the spring seats. A couple of the spring locators didn’t sit flat on the seat. It turns out the inner diameters were catching on the valve guides. A quick debur resolved that.

Installing the exhaust valve seals

Intake valve seals

Installing the valves. Dished valves are lighter than flat faced valves and I don’t need any more compression.

All the valves installed

All the valves, seats and seals installed

Cleaning the rockers, bolts and lost motion assemblies.

Preparing the springs and retainers.

Compressing the valve springs to insert the keepers. I love this valve spring compressor. It lets me compress the springs by myself and frees up both hands to insert the keepers. Impossible with a generic lever type compressor.

All the springs and retainers installed.

Here’s the finished pic in daylight

Last edited:

randomhobo

automagic user

I think I'm in love with this thread, where can we find a compressor like that, looks easier then my snap-on one.

Muckman

Not a M0derator

I got it right from the manufacturer

http://www.euroexportinc.com/store/tools/valve-spring-tools.html

They make it for B/H/K series heads, also non vtec.

Simply the best spring compressor Ive ever worked with.

http://www.euroexportinc.com/store/tools/valve-spring-tools.html

They make it for B/H/K series heads, also non vtec.

Simply the best spring compressor Ive ever worked with.

Muckman

Not a M0derator

Because I feel Supertech has a good name for themselves and their valves are probably the most common in the industry.

Ferrea is absurdly expensive and their website blows.

They couldnt tell me what the difference was between their competition and competition plus series valves.

When I priced out the full valvetrain, Ferrea was twice as much as Supertech for all the parts. I couldnt see that much difference in quality.

Ferrea is absurdly expensive and their website blows.

They couldnt tell me what the difference was between their competition and competition plus series valves.

When I priced out the full valvetrain, Ferrea was twice as much as Supertech for all the parts. I couldnt see that much difference in quality.