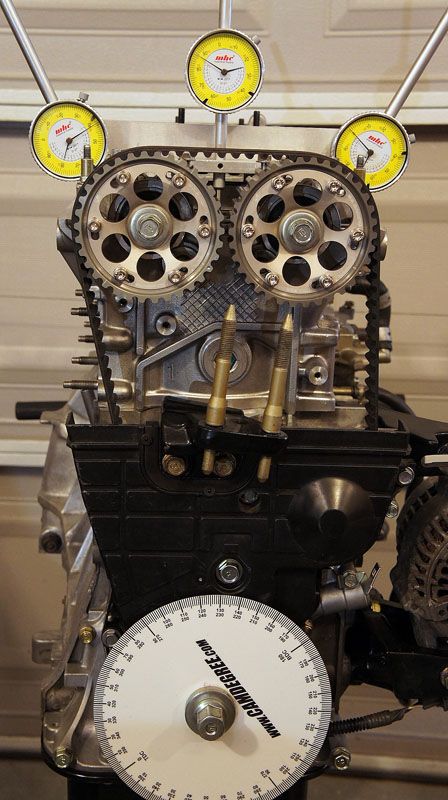

I used my "Mike Belben kit" to measure p2v and degree the

GSC T1 cams.

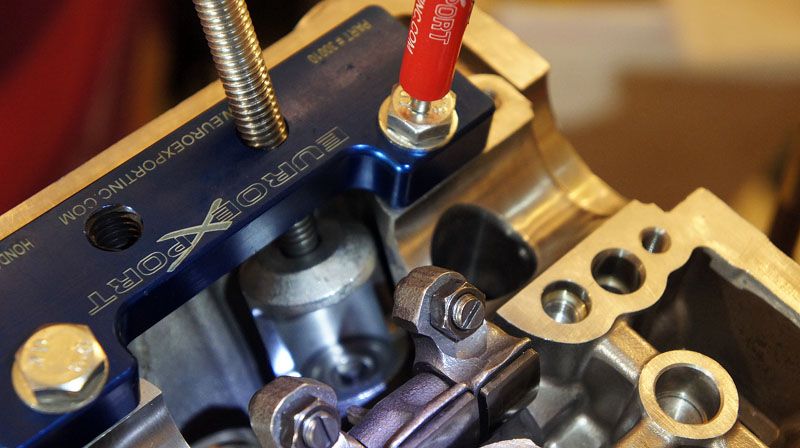

Using the EuroExport tool to easily replace the stiff valve springs with soft ones that come with the kit.

The soft valve spring makes it easy to push the valve down by hand to measure p2v.

This technique is faster than using clay but it’s more complex. With VTEC locked set the piston to TDC on the exhaust stroke. This is the closest p2v angle. Zero the dial indicator then push down on the retainer to measure p2v clearance. The issue I had with this was the narrow soft valve spring would allow the retainer to tilt and pop out the keepers.

For the most part my p2v measurements were consistent with what I had measured last year with clay. Keep in mind I decreased the compression height of the wrist pin .005” with the custom pistons and the deck was milled so I don’t expect the same clearances but Im looking for consistency.

Last year with Clay

Cams@/intake/exhaust

+6, .016, .170

+3, .040, .140

0, .068, .110

-3, .093, .090

-6, .110, .060

See how the numbers are consistent and form a nice trend line? You could plot these data points and get a straight line.

This year with Dial Indicators

Cams@/intake/exhaust

+6, .026, .107*

+4, .049, .089*

+2, .072, .157*

0, .093, .139

-2, .113, .118

-4, .139, .095

-6, .095 .071

As you can see it’s somewhat in line with last year except for the 3 exhaust with a *. I rechecked them 3 times but they are still inconsistent with the trend line. The .089” at +4 exhaust is really far out there. I’ll disregard these 3 exhaust measurements as they aren’t in the danger zone anyways.

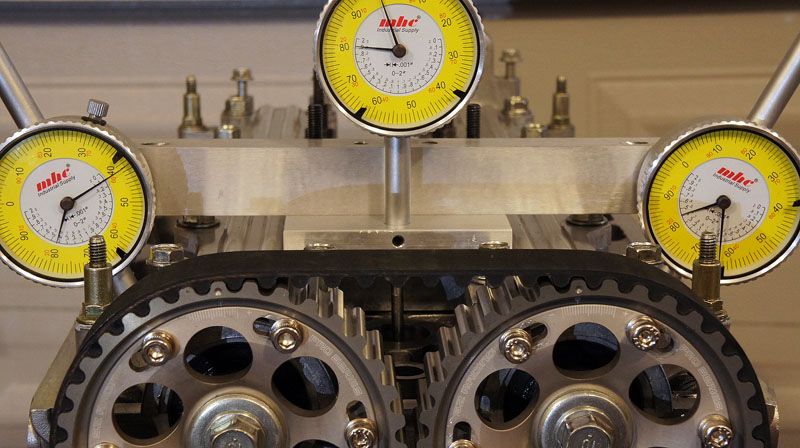

I used the

centerline method to degree the cams. The cam card says peak lift occurs at 109* ATDC (intake) and 115* BTDC (exhaust). Simply turn the crank to those angles and rotate cam gears until indicator shows maximum valve lift.

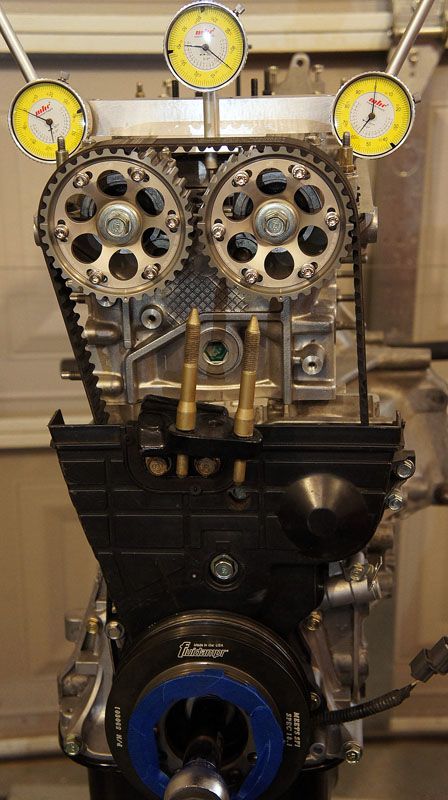

I was surprised how accurate the mark on the lower tbelt cover was. Using the dial indicators to find true TDC then adjust the degree wheel to match. The tbelt cover was right on TDC. I was going to setup a wire pointer but I couldn’t it any better than the tbelt indicator.

Removed crank damper and installed degree wheel. With piston at TDC adjust degree wheel so indicator points at 0* TDC.

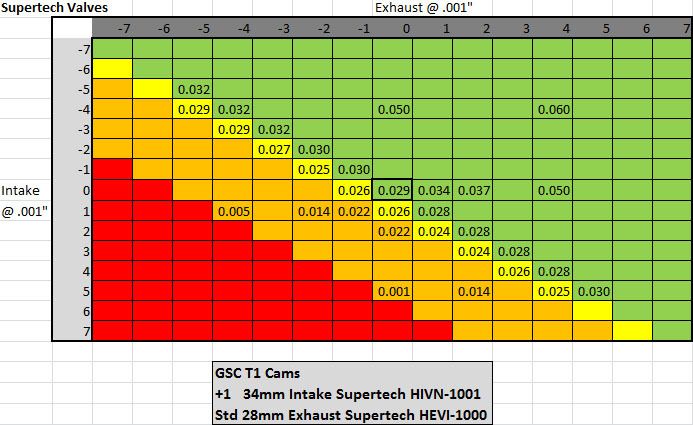

I ended up at with centerlines at -4* intake and +4* exhaust. Before continuing with these settings I must make sure I have adequate p2v and v2v clearances. Using my measurements from above my p2v at -4I/+4E are both greater than .060”. And using my v2v chart from last year my v2v is greater than .030”.

After completing my valvetrain measurements I reinstalled the valve springs and rockers then set valve lash to .009" cold.