IntegraDB2

New Member

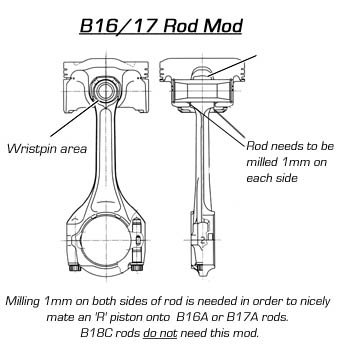

i was wondering if anyone was certain on compression ratios. on my B17 i am currenlty rebuilding i want to up the compression from stock 9.7 to 1 . to atleast 11 to 1 maybe 11.5 to 1. i am looking at getting either ctr or itr pistons ( i would imagine this will put me in my desired comp. range) does anyone know the compression ratio i would get out of these.?? also what about clearence with valves (down the road skunk2 pro series stage 2 cams) will be inserted will my valves still have plenty if clearence? one last thing will either of these pistons cause me to have to get my rods shaved for clearence with the head or will they bolt of to stock crank and rods ? advice much appreciated