Muckman’s High Compression Super Build

Muckman

Not a M0derator

After inspecting all the evidence what we think happened was the rods were stretched by the heavier pistons this year and we didn’t have enough piston to head clearance to cover it.

Relevant build specs:

Rod bearing clearance - .0018”

Main bearing clearance - .0020”

P2H quench clearance - .035”

Oil pressure - ~100psi peak

New ARP2000 3/8” rod bolts torqued to 50ft-lbs with a calibrated torque wrench.

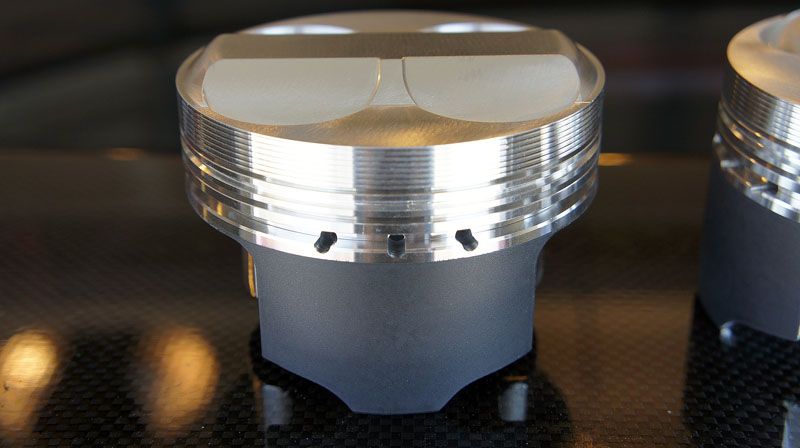

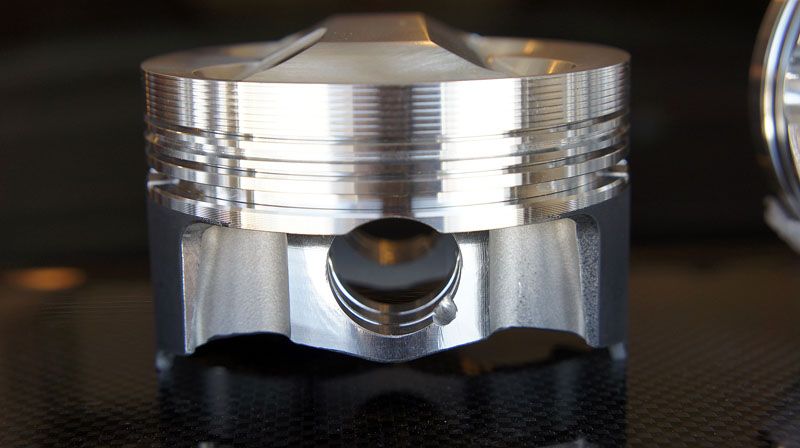

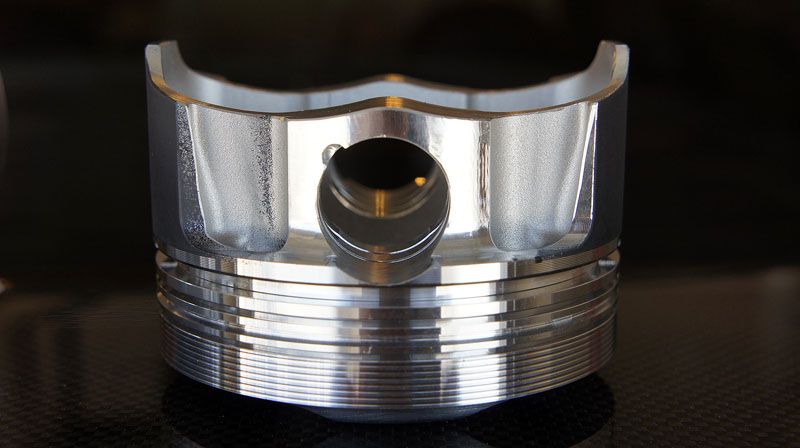

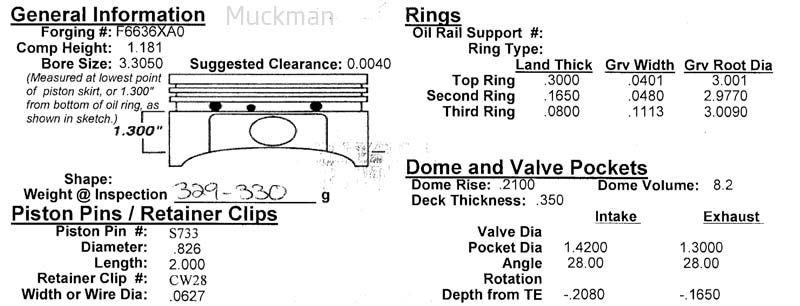

2012 engine ran the same oil pump, crank, rods, bearing and quench clearances at 9200rpm a dozen times without issue. That establishes a clear baseline for this engine. The only significant change to the rotating assembly for 2013 was the custom pistons and upgraded wrist pin.

Piston weight went from 279g to 338g.

Wrist pin weight went from 68g to 108g.

Total weight went from 347g to 446g for an increase of 99g or 29%

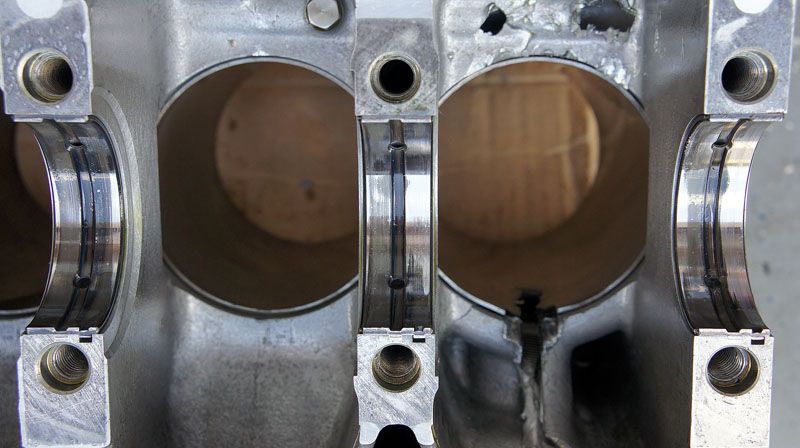

Evidence of ALL pistons hitting the head. Note the ceramic coating is gone from all the quench pads on exhaust sides of all 4 pistons.

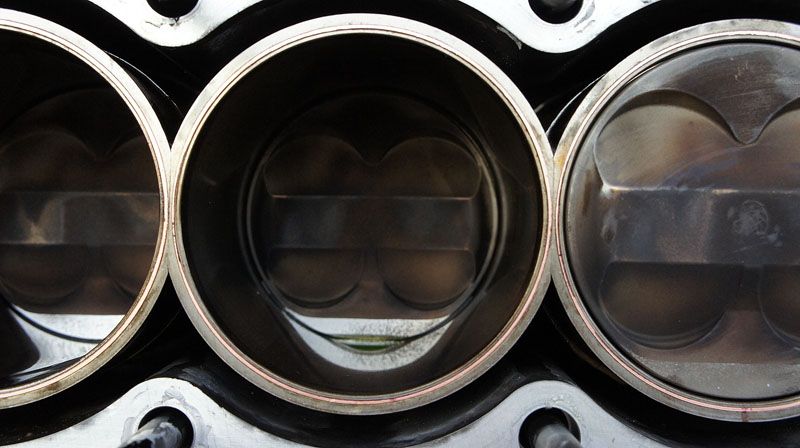

Close up of pistons 3,2,1. You can see the ceramic is gone on the exhaust side of the piston.

Head chambers 1,2,3. Fortunately the head is OK. I would have thrown in the towel if it was destroyed.

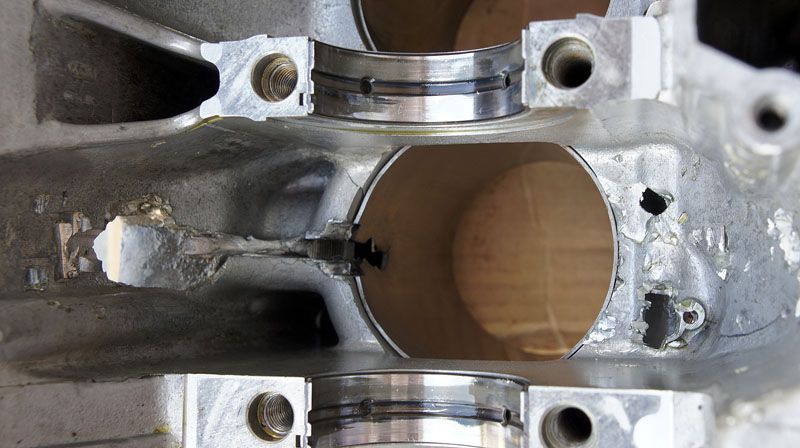

Here the worst of the head damage on #4. The surface slightly above the valves is squished. I don’t think this is significant and can be blended out by hand. Worst case the head would need to be resurfaced.

Notice the copper Oring was burnt around #4. Probably lifted from contact. Its clean around every other cylinder.

#4 also had a little bit of coolant on the piston and around the valves. But it wasn't full of coolant.

There rod big show some but not a lot of discoloration from overheating you’d expect from prolongued friction due to a spun bearing. This went very quick.

All the remaining bearings were distressed, especially #1. It was clear all rods suffered the same torture. Only #4 was the first to let go.

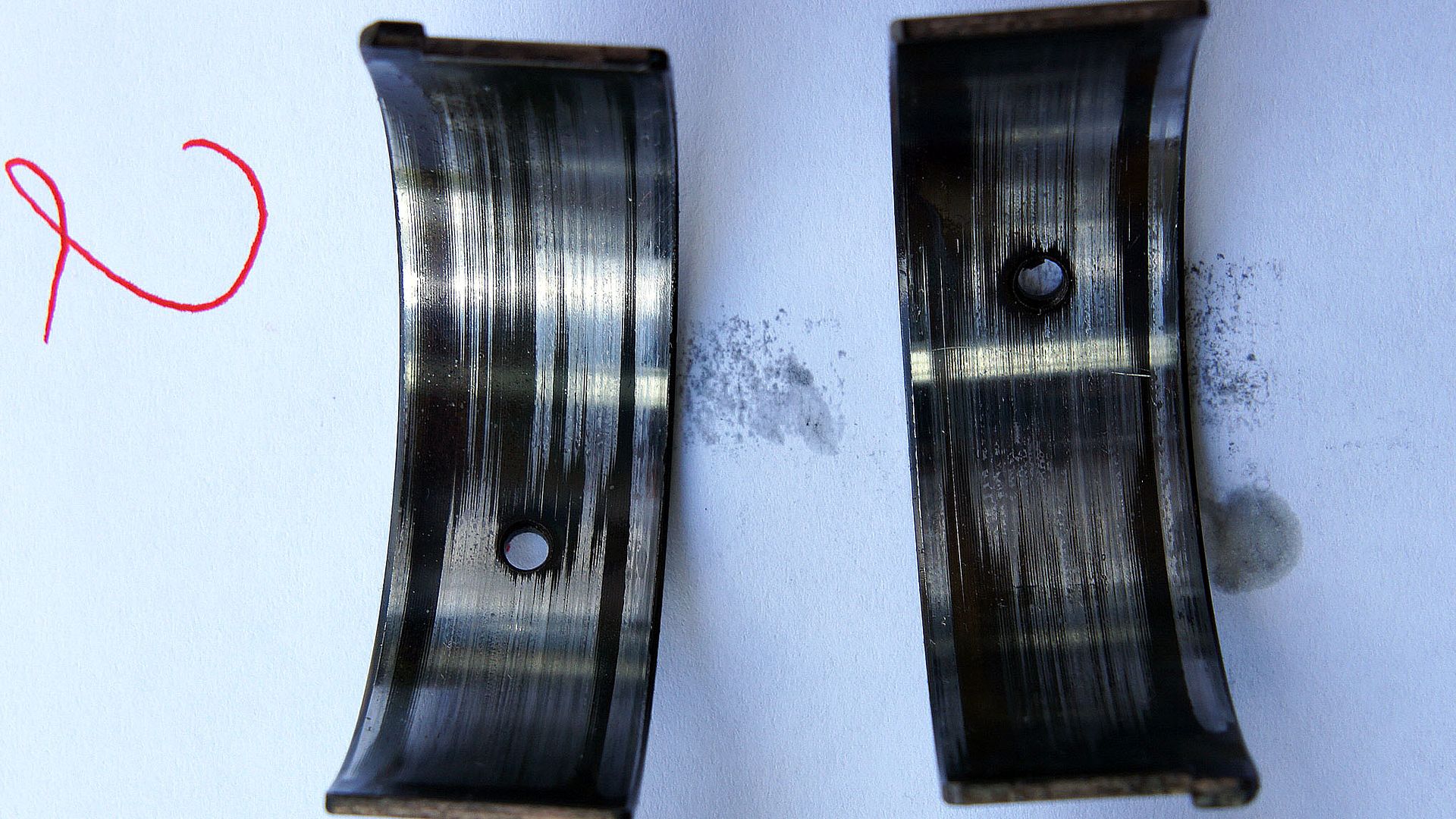

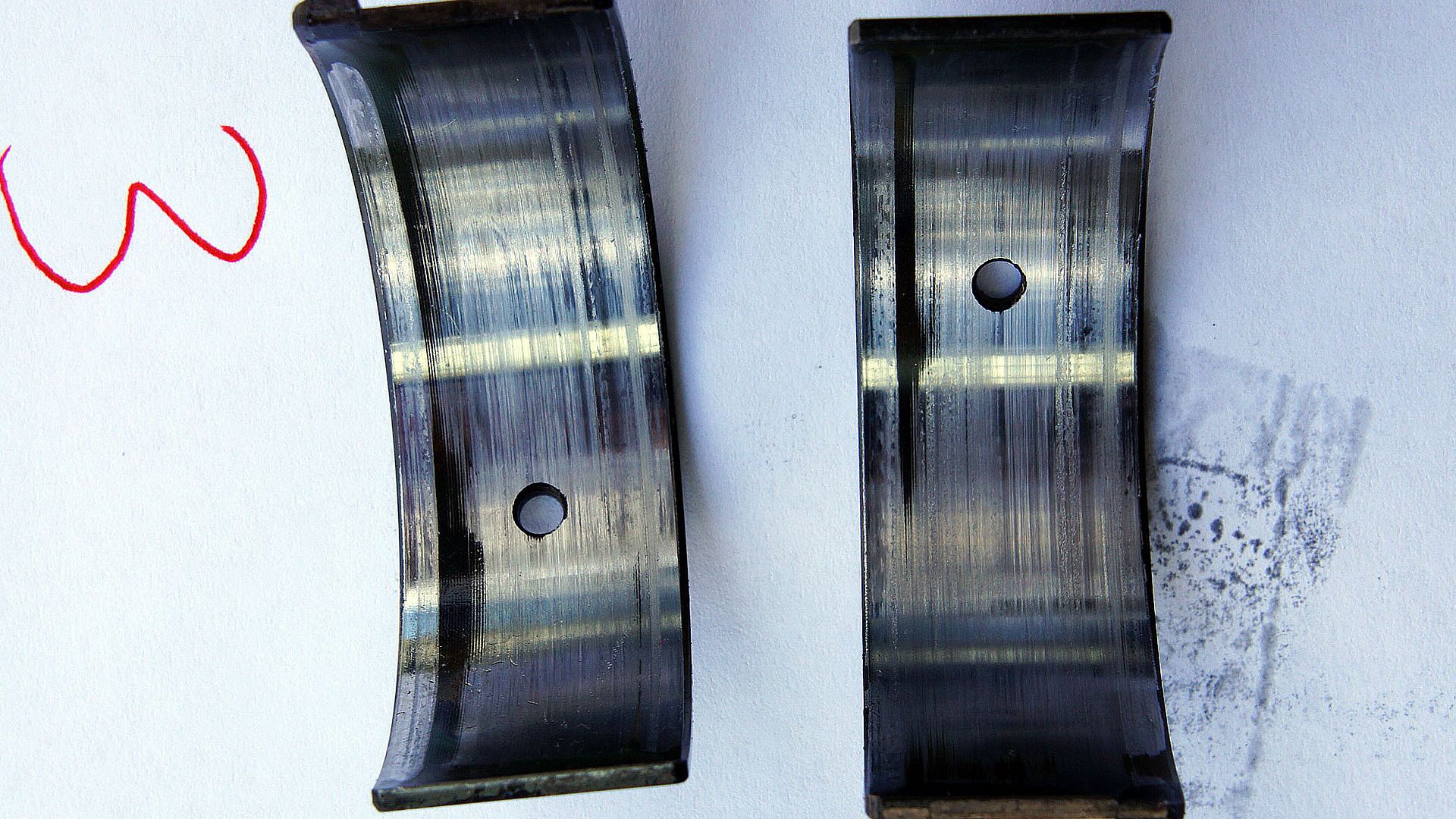

#1 rod bearings severely damaged but not spun.

These are ACL Race HX bearings which have a black coating when new.

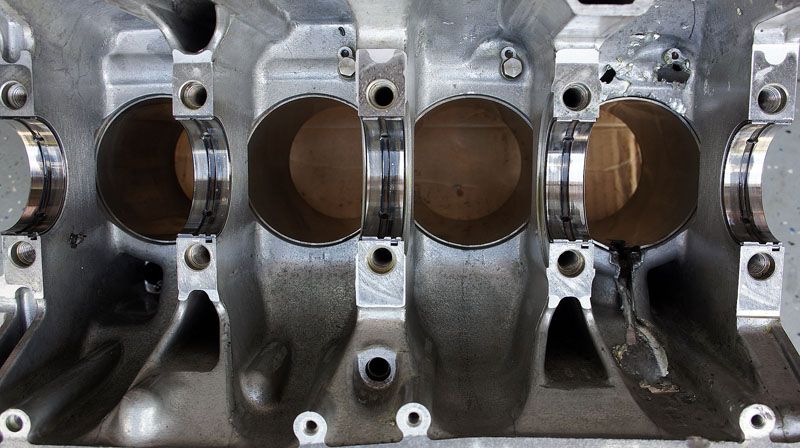

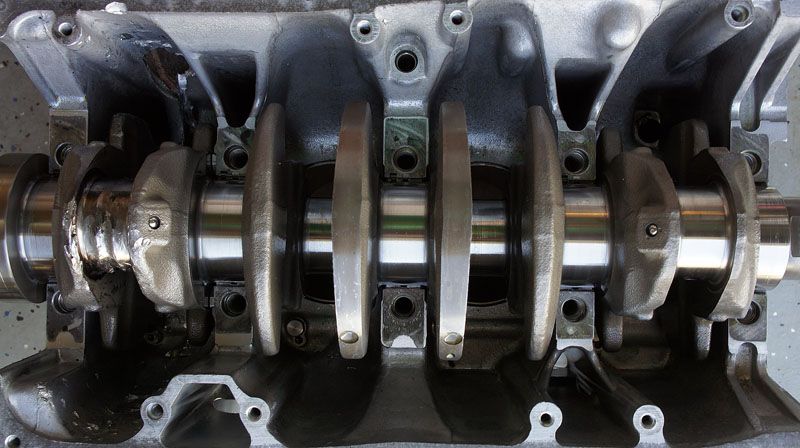

All Upper mains

Upper Mains 3,4,5

Upper Mains 5,4 - uneven wear

All Lower Mains

Lower Mains 1,2

Lower Main 3

Lower Mains 5,4

All crank journals – as you can see the crank looks pretty good – aside from rod4. Even Rod1 journal looks fine.

Definitely not the scaring and discoloration we’d expect from prolonged friction.

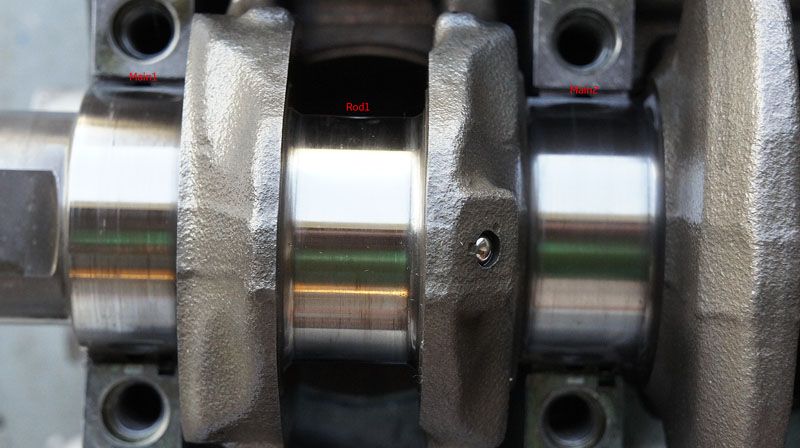

Crank journals – Main 2, Rod1, Main1. Rod 1 was the next most severely damaged rod bearing.

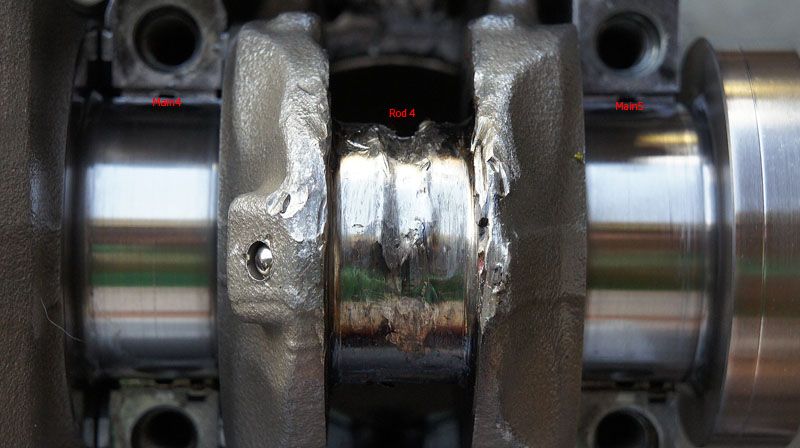

Crank journals – Main2, Rod4, Main5

Back of rod bearing #1. Hmm notice the horizontal marking on the parting line. This rubbing was present on the backs of all rod bearings.

Smoking gun. The horizontal marking of the back of the bearing at the parting line is evidence that the big end of the rod was deforming under load. This caused the bearing to pinch at the parting line and rub. The rub marks are clear on the backs of all remaining 3 rods and all remaining bearings. *See above 3 pictures

I had recorded the new ARP rod bolt lengths before installation. Of the 6 remaining bolts 3 were unchanged and 3 were .0005” longer. ARP says half a thou is the service limit so those 3 are stretched. 2 of the 3 stretched bolts were on #1 rod, not surprisingly.

I took my 3 remaining rods to my machine shop to get their opinion. They measured the rods and all 3 were out of round half a thou or more. This is within spec.

Based on the evidence we know the rods had stretched enough so the pistons reached the head .035” away. This impact likely lifted the head momentarily causing the head gasket to leak around #4 where it was most severe. As the rod big end deformed under the load of the heavy piston at speed the big end stretched pinching the rod bearings at the parting line losing oil clearance and oil wedge (there's your oil starvation). The crank journal eventually grabbed the bearing causing it to spin. Or the rod deformed enough to snap the rod bolts. There is some but not a lot of heat discoloration on the rod big ends showing there wasn't much time spent with a spun bearing, if any, before the rod bolts broke. The crank whipped the loose rod around like Thor's hammer smashing into the bottom of the sleeve and crushing the water jacket, eventually venting the block.

Relevant build specs:

Rod bearing clearance - .0018”

Main bearing clearance - .0020”

P2H quench clearance - .035”

Oil pressure - ~100psi peak

New ARP2000 3/8” rod bolts torqued to 50ft-lbs with a calibrated torque wrench.

2012 engine ran the same oil pump, crank, rods, bearing and quench clearances at 9200rpm a dozen times without issue. That establishes a clear baseline for this engine. The only significant change to the rotating assembly for 2013 was the custom pistons and upgraded wrist pin.

Piston weight went from 279g to 338g.

Wrist pin weight went from 68g to 108g.

Total weight went from 347g to 446g for an increase of 99g or 29%

Evidence of ALL pistons hitting the head. Note the ceramic coating is gone from all the quench pads on exhaust sides of all 4 pistons.

Close up of pistons 3,2,1. You can see the ceramic is gone on the exhaust side of the piston.

Head chambers 1,2,3. Fortunately the head is OK. I would have thrown in the towel if it was destroyed.

Here the worst of the head damage on #4. The surface slightly above the valves is squished. I don’t think this is significant and can be blended out by hand. Worst case the head would need to be resurfaced.

Notice the copper Oring was burnt around #4. Probably lifted from contact. Its clean around every other cylinder.

#4 also had a little bit of coolant on the piston and around the valves. But it wasn't full of coolant.

There rod big show some but not a lot of discoloration from overheating you’d expect from prolongued friction due to a spun bearing. This went very quick.

All the remaining bearings were distressed, especially #1. It was clear all rods suffered the same torture. Only #4 was the first to let go.

#1 rod bearings severely damaged but not spun.

These are ACL Race HX bearings which have a black coating when new.

All Upper mains

Upper Mains 3,4,5

Upper Mains 5,4 - uneven wear

All Lower Mains

Lower Mains 1,2

Lower Main 3

Lower Mains 5,4

All crank journals – as you can see the crank looks pretty good – aside from rod4. Even Rod1 journal looks fine.

Definitely not the scaring and discoloration we’d expect from prolonged friction.

Crank journals – Main 2, Rod1, Main1. Rod 1 was the next most severely damaged rod bearing.

Crank journals – Main2, Rod4, Main5

Back of rod bearing #1. Hmm notice the horizontal marking on the parting line. This rubbing was present on the backs of all rod bearings.

Smoking gun. The horizontal marking of the back of the bearing at the parting line is evidence that the big end of the rod was deforming under load. This caused the bearing to pinch at the parting line and rub. The rub marks are clear on the backs of all remaining 3 rods and all remaining bearings. *See above 3 pictures

I had recorded the new ARP rod bolt lengths before installation. Of the 6 remaining bolts 3 were unchanged and 3 were .0005” longer. ARP says half a thou is the service limit so those 3 are stretched. 2 of the 3 stretched bolts were on #1 rod, not surprisingly.

I took my 3 remaining rods to my machine shop to get their opinion. They measured the rods and all 3 were out of round half a thou or more. This is within spec.

Based on the evidence we know the rods had stretched enough so the pistons reached the head .035” away. This impact likely lifted the head momentarily causing the head gasket to leak around #4 where it was most severe. As the rod big end deformed under the load of the heavy piston at speed the big end stretched pinching the rod bearings at the parting line losing oil clearance and oil wedge (there's your oil starvation). The crank journal eventually grabbed the bearing causing it to spin. Or the rod deformed enough to snap the rod bolts. There is some but not a lot of heat discoloration on the rod big ends showing there wasn't much time spent with a spun bearing, if any, before the rod bolts broke. The crank whipped the loose rod around like Thor's hammer smashing into the bottom of the sleeve and crushing the water jacket, eventually venting the block.

randomhobo

automagic user

It;s sad to see this happen to such a great build but we all know you will come up with something bigger and better with the new year! Best of luck with the new beginnings!

Muckman

Not a M0derator

Hah yeah I'll add that crank to pile of 4 others that I've ruined over the past 8 years. Maybe one day I can get some money for scrap metal. Well that block is garbage now so the p2h issue goes away with a new block that's not decked to death.

Since I blew this up in July, I went a little nuts buying blocks.

-I bought that low compression Golden Eagle sleeved GSR block.

-Then I scored a MINT RS sleeved ITR bare block for cheap. I decided to resell this because it had been milled too much and bore was too big to start over with.

-Then I bought 2 more virgin GSR blocks.

-Sold the GE short block.

-Trying to sell the ITR block.

-And send one of the virgin blocks out to get sleeved.

-Im keeping the other virgin block for a back up.

The ITR block came with a fully machined and ready to go GSR crank (polished, balanced, drilled plugs out, cleaned and capped). But Ive always used the longer stroke LS cranks. So Im trying to decide use the GSR crank or look for another LS crank and invest a couple hundred to get it where it needs to be.

And then I have to decide on bore. Would like to be big but not too big so I have a number of rebuilds in the block. Maybe 83mm? Decisions. Decision. But I have everything figured out.

Since I blew this up in July, I went a little nuts buying blocks.

-I bought that low compression Golden Eagle sleeved GSR block.

-Then I scored a MINT RS sleeved ITR bare block for cheap. I decided to resell this because it had been milled too much and bore was too big to start over with.

-Then I bought 2 more virgin GSR blocks.

-Sold the GE short block.

-Trying to sell the ITR block.

-And send one of the virgin blocks out to get sleeved.

-Im keeping the other virgin block for a back up.

The ITR block came with a fully machined and ready to go GSR crank (polished, balanced, drilled plugs out, cleaned and capped). But Ive always used the longer stroke LS cranks. So Im trying to decide use the GSR crank or look for another LS crank and invest a couple hundred to get it where it needs to be.

And then I have to decide on bore. Would like to be big but not too big so I have a number of rebuilds in the block. Maybe 83mm? Decisions. Decision. But I have everything figured out.

Nick_C78

New Member

I thought the 3 cranks I had laying around was bad... At least only 2 of those are bad. I have 1 spare. Highly recommend always having a spare crank on hand.

That is a bunch of blocks. I would go with a larger displacement setup right now, but I figure I wanna see how high I can get this 1.8 on oem cams before it dies. Then I will just go K.

If I were you I would go 83. Leaves room for error. Good to hear that your P2H issue is fixed with a simple fresh block.

That is a bunch of blocks. I would go with a larger displacement setup right now, but I figure I wanna see how high I can get this 1.8 on oem cams before it dies. Then I will just go K.

If I were you I would go 83. Leaves room for error. Good to hear that your P2H issue is fixed with a simple fresh block.

Nick_C78

New Member

Quit crying and get your custom pistons, or settle for 84mm and realize that the life of the block will be less. The likelihood is that something else will break and kill the block before you need to refresh the motor with a new bore anyways. That being said I personally would just go 84mm. However, I do like the word "custom". In fact my new valves are being custom made out of blanks, because we can.